Manufacturing Success.

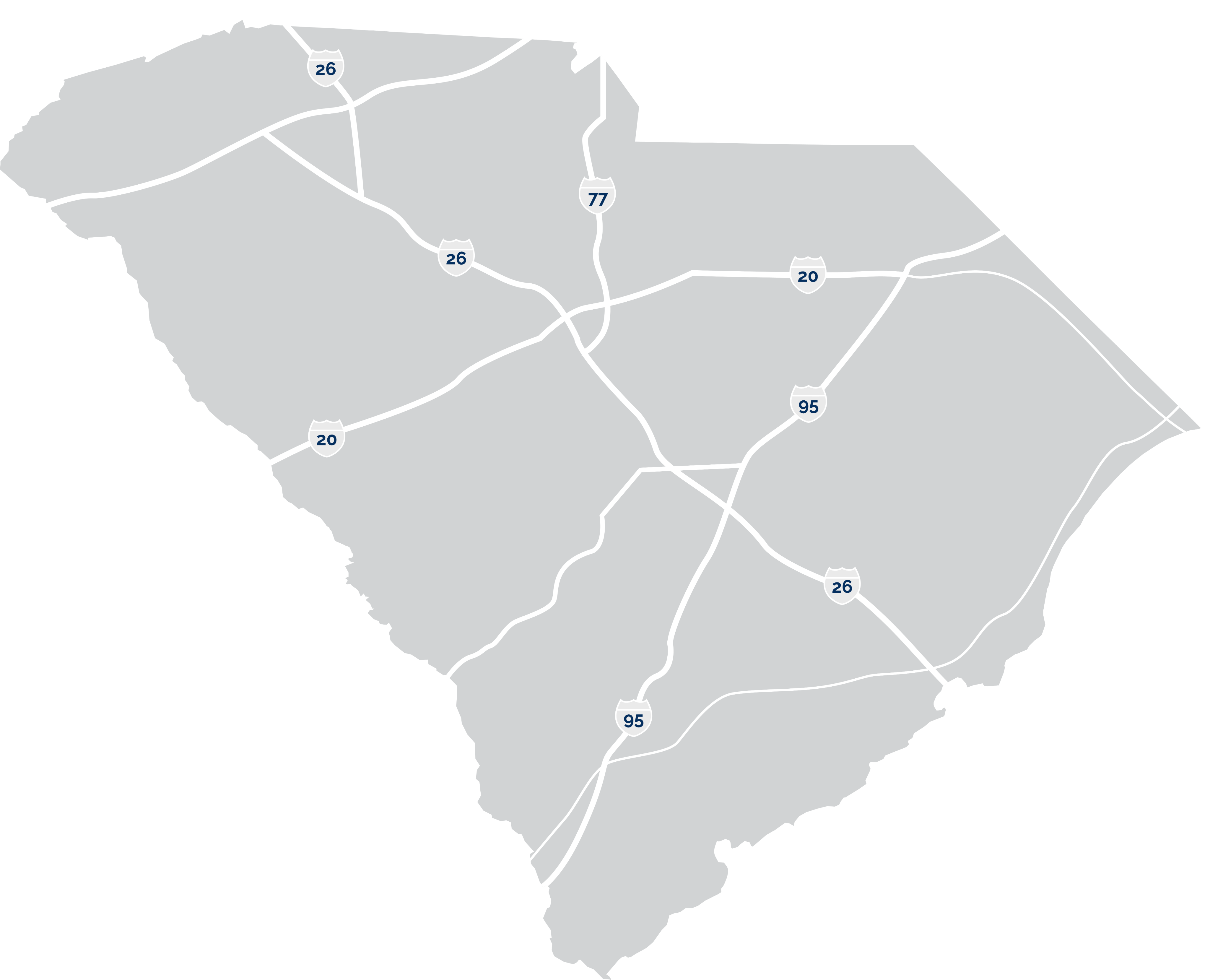

C.R. Jackson operates six state-of-the-art asphalt plants, strategically located across South Carolina to serve the DOT, private industry, and commercial development. At these plants, we manufacture asphalt for our own use and also supply it to other contractors and local municipalities.

C.R. Jackson, Inc. Asphalt Plants are environmentally conscious and equipped to produce a high-quality asphalt mix.

Asphalt Production Pioneers.

We work closely with one of the country’s leading manufacturers of asphalt road-building equipment. This partnership gives us access to the most up-to-date equipment, helping to maintain our asphalt mixture and keep costs down.

Our asphalt plants are equipped with the Astec Green System, enabling us to produce environmentally friendly warm-mix asphalt. This method offers our customers cost savings, extended workability, and reduced paving temperatures.

We work closely with one of the country’s leading manufacturers of asphalt road-building equipment. This partnership gives us access to the most up-to-date equipment, helping to maintain our asphalt mixture and keep costs down.

Our asphalt plants are equipped with the Astec Green System, enabling us to produce environmentally friendly warm-mix asphalt. This method offers our customers cost savings, extended workability, and reduced paving temperatures.

Award-Winning Operations.

Since 2006, every C.R. Jackson asphalt plant has received the Diamond Achievement Commendation from the National Asphalt Pavement Association, highlighting our daily commitment to safety and efficiency.

Since 2006, every C.R. Jackson asphalt plant has received the Diamond Achievement Commendation from the National Asphalt Pavement Association, highlighting our daily commitment to safety and efficiency.

100% Recyclable Asphalt.

Because we know your budget is important to you, we try to save our partners as much money as possible without compromising the quality of the final product.

That’s why we use 100% recycled asphalt products (RAP) on projects that allow for it. This recycled material, generated from our milling operations, reduces the cost of our asphalt mixture, allowing us to pass those savings along to you.

Because we know your budget is important to you, we try to save our partners as much money as possible without compromising the quality of the final product.

That’s why we use 100% recycled asphalt products (RAP) on projects that allow for it. This recycled material, generated from our milling operations, reduces the cost of our asphalt mixture, allowing us to pass those savings along to you.

Our Asphalt Plants.

We’re positioned to serve the broader Midlands, PeeDee, and Lowcountry regions of our state. Our six asphalt plants across South Carolina not only support our projects but are also available for local municipalities and third-party contractors wanting to purchase quality mix.

We’re positioned to serve the broader Midlands, PeeDee, and Lowcountry regions of our state. Our six asphalt plants across South Carolina not only support our projects but are also available for local municipalities and third-party contractors wanting to purchase quality mix.